Installations & Orderbook

See how our suction sails are bringing real results and check our latest and upcoming installations

Discover the power of our eSAILs® for your fleet. Real results from real customers, including improved fuel efficiency, increased speed, reduced emissions and regulatory compliance.

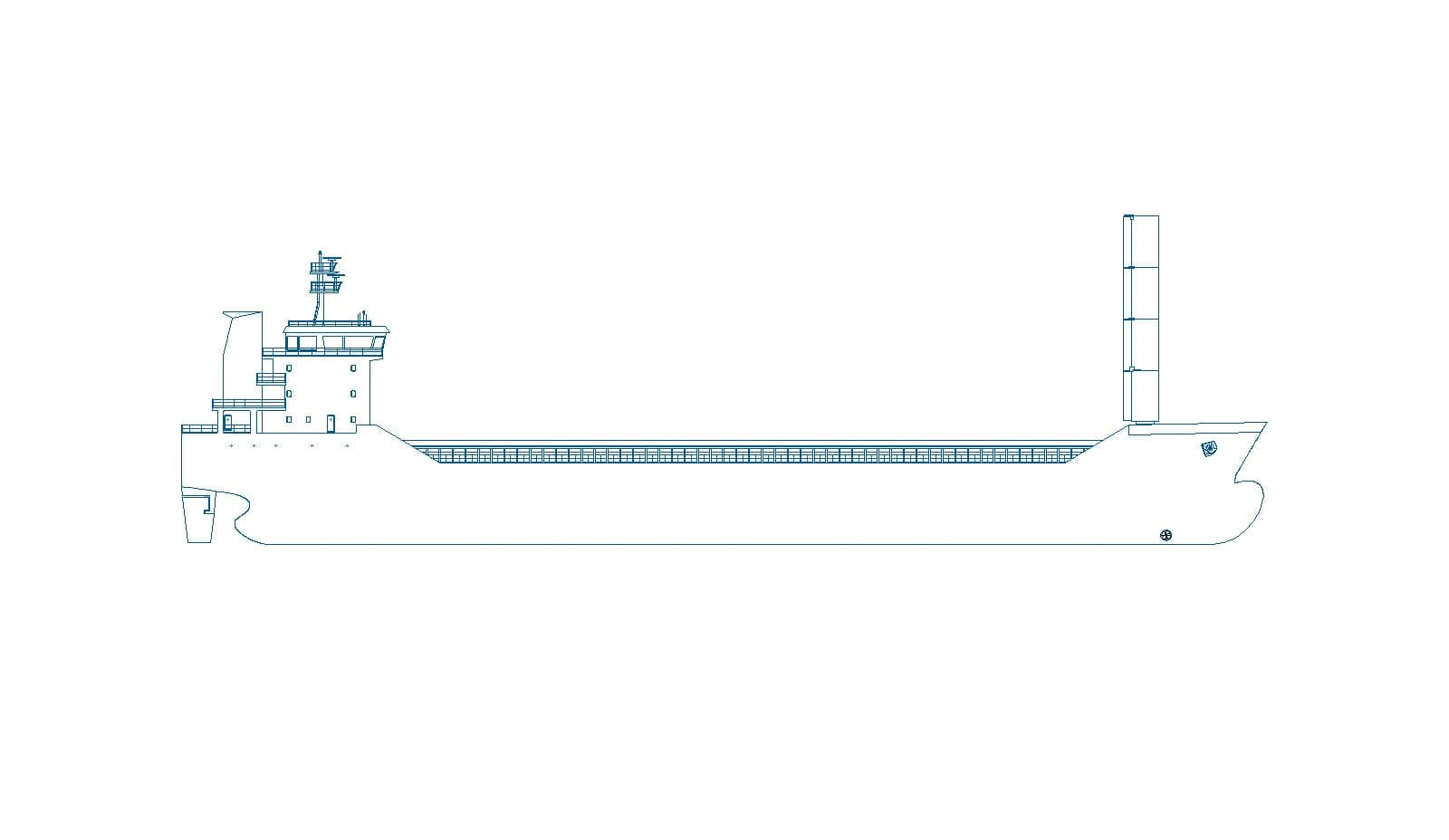

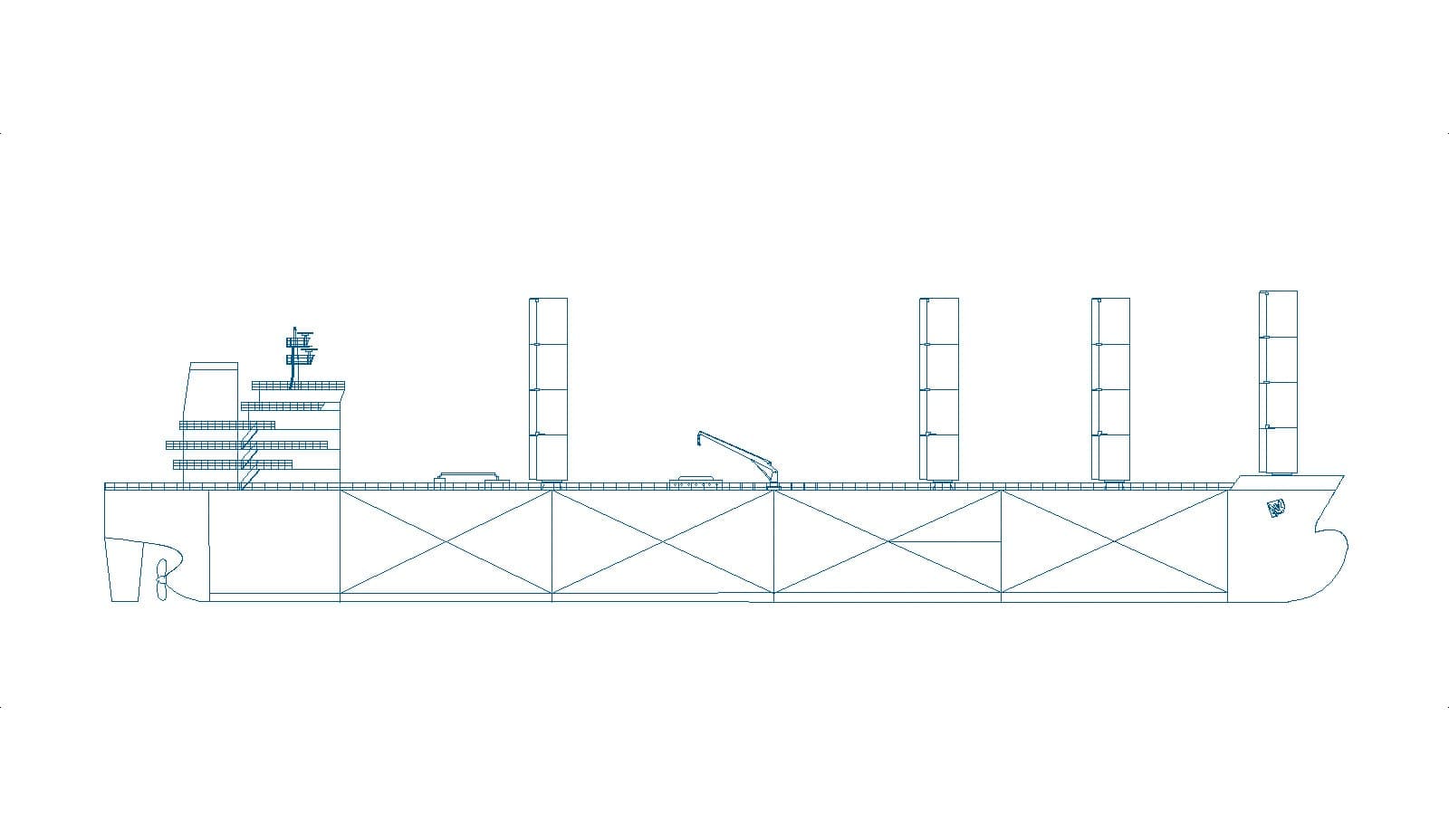

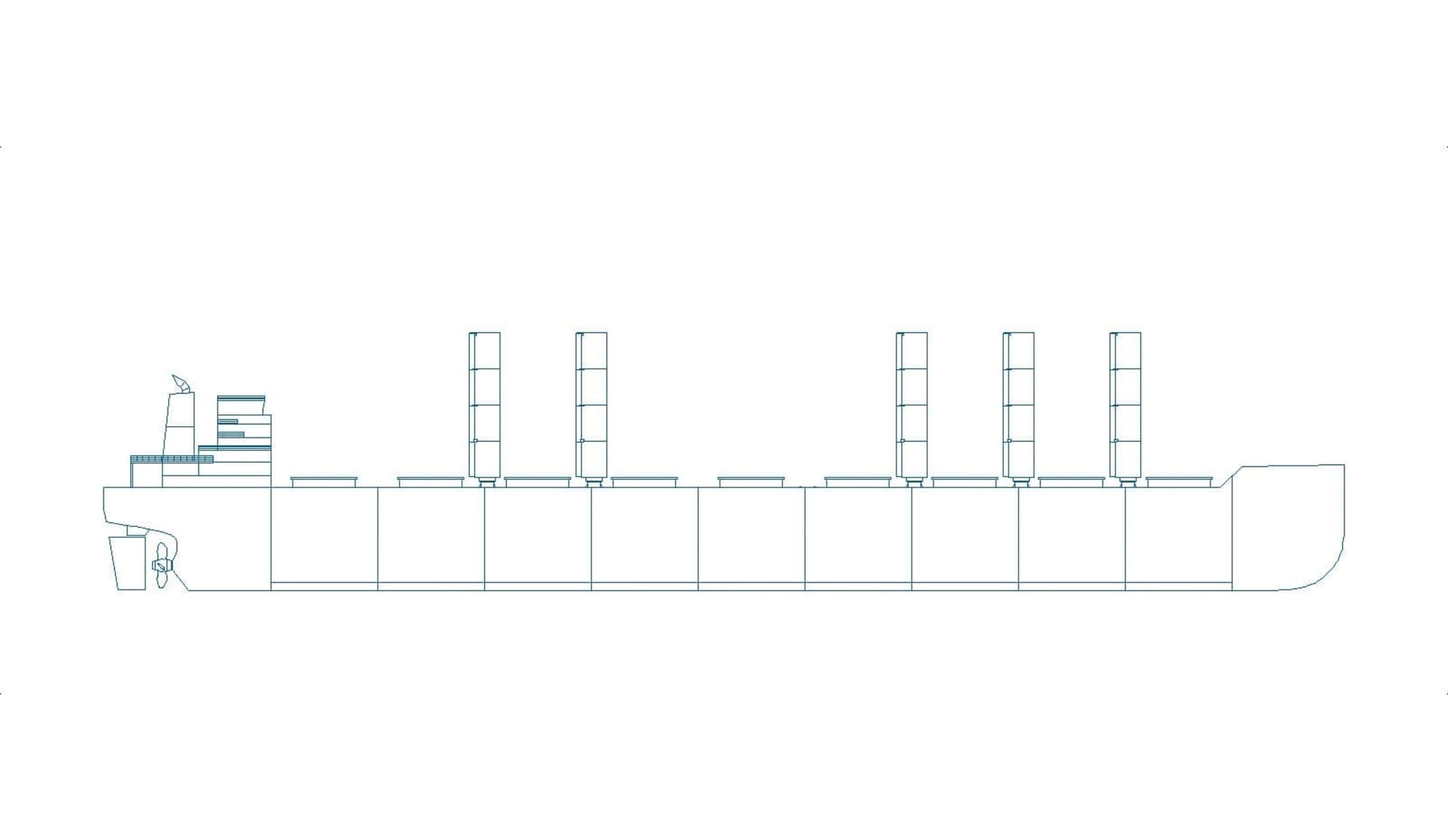

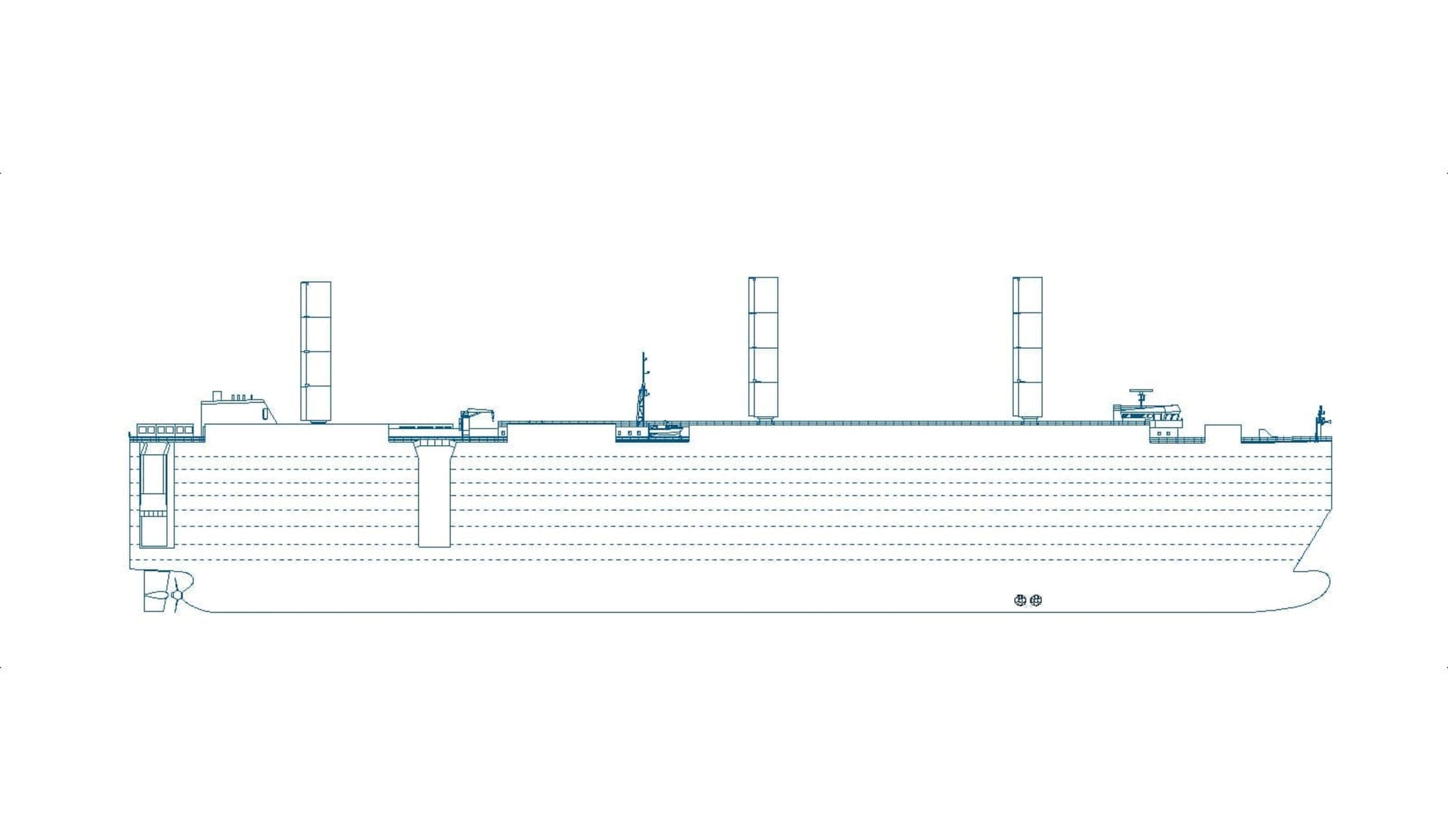

With our portfolio of safe, proven, and reliable eSAIL® models – and other optional add-on solutions – we can provide a turn-key solution for Tankers, Bulkers, Ro-Ros, Cruises, Ferries and General Cargo vessels, regardless of their size or if it’s a new build or an existing ship.

As of today

eSAILs®

Ships

Next installations

eSAILs®

Ships

Expertise across

different segments

Select category

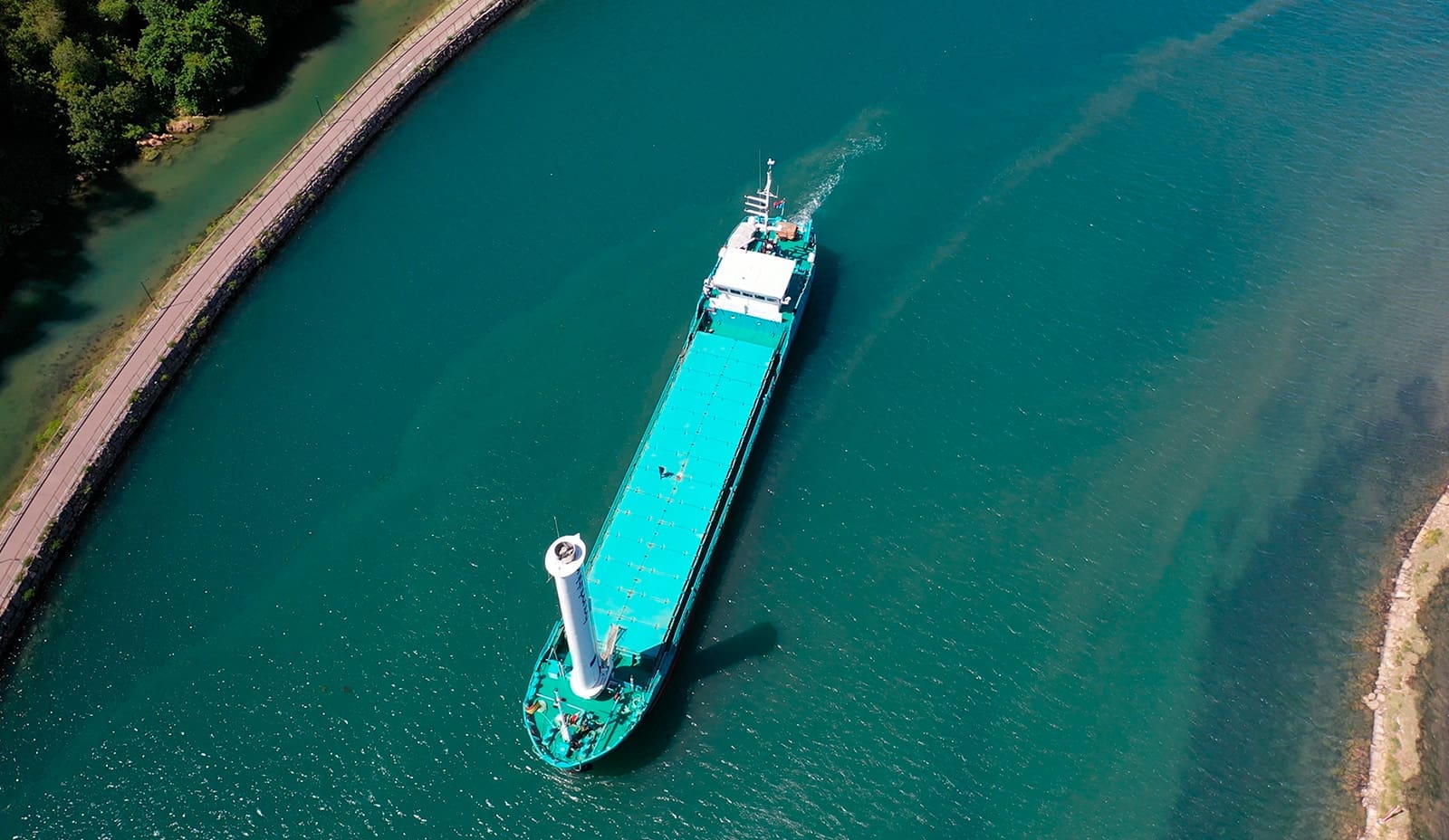

EEMS Traveller

Application: 90m LOA general cargo

Configuration: x2 units Model 1 - 17 x 2.85 m

Completion: June 2023

La Naumon

Application: 62m LOA General Cargo

Configuration: x1 unit Model 1 – 17 x 2.85 m (tilting)

Completion: December 2021

Tuhaa Pae V

Application: 90m LOA Multipurpose Cargo Vessel

Configuration: x1 unit Model 2 – 22 x 4.5 m

Completion: 2026

Fluvius Tavy

Configuration: x1 unit Model 2 – 22 x 4.5 m

Ville de Bordeaux

Application: 154m LOA Ro-Ro

Configuration: x3 units Model 2 – 22 x 4.5 m

Completion: February 2024

Crimson Kingdom

Application: 229m LOA panamax

Configuration: x4 units Model 2 – 26 x 4.5 m (tilting)

Completion: N/A

Balueiro Segundo

Application: 37m LOA longliner

Configuration: x1 unit Model 1 – 12 x 2.85 m

Completion: May 2021

Bow Olympus

Application: 183m LOA

Configuration: x4 units Model 2 – 22 x 4.5 m

Completion: 2024

Pacific Sentinel

Application: 183m LOA

Configuration: x3 units Model 2 – 22 x 4.5 m

Completion: 2024

Santiago I

Application: 183m LOA

Configuration: x4 units Model 2 – 22 x 4.5 m

Completion: 2025

Maersk Tankers

Application: Maersk Tacoma, Maersk Tokyo, Maersk Tampa, Maersk Tangier, Maersk Teesport

Configuration: x4 units Model 3 – 24 x 6 m (each vessel)

Newbuild

Configuration: x2 units Model 2 – 22 x 4.5 m

Atlantic Orchard

Application: 180m LOA

Configuration: x4 units Model 2 – 26 x 4.5 m

Completion: 2024

CABU III

Configuration: x2 unit Model 2 – 24 x 4.5 m

Helena Kosan

Configuration: x1 unit Model 3 – 24 x 4.5 m

Six steps to

start saving fuel

-

01

CONTACT AND PRELIMINARY STUDY

-

02

OPTIMAL ARRANGEMENT SELECTION OF SAILS

-

03

SAILS INSTALLATION DESIGN AND APPROVAL

-

04

VESSEL PREPARATION

-

05

INSTALLATION OF BOUND4BLUE SAILS

-

06

WELCOME TO THE BLUE EFFICIENCY

-

Get in touch and we will carry out a free-of-charge preliminary business case for you, providing an estimation of expected savings and ROI period, as well as some tips to better understand the application of wind-assisted propulsion systems.

We just need you to provide some general information on your fleet and sailing areas. Calculations, based on years-long historical weather data will be done by our proprietary performance prediction software tool.

-

We will perform a detailed analysis to select the optimal general arrangement of your sail-assisted vessel. In other words, we will select the most appropriate number, size and location of bound4blue suction sails for your vessel and operation.

-

The selection considers several general and vessel-specific factors, including:

-

Geometry and structure – Available deck space, existing deck equipment and piping, deck-hull structure for installation of foundations, etc.

-

Aerodynamic interference – between sails, with vessel superstructures and other deck equipment.

-

Rules and regulation – Stability, visibility from bridge, navigation lights, radar, etc.

-

Safety and operations – Air draught, cargo operations, etc.

-

-

When the optimal general arrangement has been selected, a detailed vessel transformation project will be done, ensuring that the resulting vessel complies with all applicable rules and regulations. Note that this is like the process followed to install a marine deck crane.

The transformation project will include, among others:

-

Detailed stability, bridge visibility and navigation light analysis.

-

Local deck reinforcement (foundations) for the installation of sails.

-

Power supply and electrical circuit diagrams.

The generated documentation from the transformation project will be submitted to the Class Society and Flagging State for approval.

-

-

Some work shall be done on the vessel prior to the installation of the sails. The significant being:

-

The manufacture and installation of the foundations where the sails will be installed.

-

The installation of cabling to provide electric power to the sails and to connect the sails with the autonomous control system components on the vessel’s bridge.

A good option to maximise cost-effectiveness is to execute this work during a scheduled regular dry-dock of the vessel.

These tasks should not take more than 1-2 weeks.

-

-

The installation of bound4blue sails is quick and simple.

The sails will be positioned on the foundations and their flanges bolted together. Cabling connections are done, and we are ready to go.

This operation can be done during the same dry-dock where the vessel is prepared or afloat at any other regular port call.

-

Thanks to bound4blue’s autonomous control system, no special crew training is required.

Just switch on the system and it will do the rest: reducing your fuel bill and pollutant emissions from day one.

-

01

CONTACT AND PRELIMINARY STUDY

Get in touch and we will carry out a free-of-charge preliminary business case for you, providing an estimation of expected savings and ROI period, as well as some tips to better understand the application of wind-assisted propulsion systems.

We just need you to provide some general information on your fleet and sailing areas. Calculations, based on years-long historical weather data will be done by our proprietary performance prediction software tool.

-

02

OPTIMAL ARRANGEMENT SELECTION OF SAILS

We will perform a detailed analysis to select the optimal general arrangement of your sail-assisted vessel. In other words, we will select the most appropriate number, size and location of bound4blue suction sails for your vessel and operation.

-

The selection considers several general and vessel-specific factors, including:

-

Geometry and structure – Available deck space, existing deck equipment and piping, deck-hull structure for installation of foundations, etc.

-

Aerodynamic interference – between sails, with vessel superstructures and other deck equipment.

-

Rules and regulation – Stability, visibility from bridge, navigation lights, radar, etc.

-

Safety and operations – Air draught, cargo operations, etc.

-

-

03

SAILS INSTALLATION DESIGN AND APPROVAL

When the optimal general arrangement has been selected, a detailed vessel transformation project will be done, ensuring that the resulting vessel complies with all applicable rules and regulations. Note that this is like the process followed to install a marine deck crane.

The transformation project will include, among others:

-

Detailed stability, bridge visibility and navigation light analysis.

-

Local deck reinforcement (foundations) for the installation of sails.

-

Power supply and electrical circuit diagrams.

The generated documentation from the transformation project will be submitted to the Class Society and Flagging State for approval.

-

-

04

VESSEL PREPARATION

Some work shall be done on the vessel prior to the installation of the sails. The significant being:

-

The manufacture and installation of the foundations where the sails will be installed.

-

The installation of cabling to provide electric power to the sails and to connect the sails with the autonomous control system components on the vessel’s bridge.

A good option to maximise cost-effectiveness is to execute this work during a scheduled regular dry-dock of the vessel.

These tasks should not take more than 1-2 weeks.

-

-

05

INSTALLATION OF BOUND4BLUE SAILS

The installation of bound4blue sails is quick and simple.

The sails will be positioned on the foundations and their flanges bolted together. Cabling connections are done, and we are ready to go.

This operation can be done during the same dry-dock where the vessel is prepared or afloat at any other regular port call.

-

06

WELCOME TO THE BLUE EFFICIENCY

Thanks to bound4blue’s autonomous control system, no special crew training is required.

Just switch on the system and it will do the rest: reducing your fuel bill and pollutant emissions from day one.