News

Why wind tunnel testing matters in the aerodynamic development of WAPS

Published

04 February 2026

In the world of aerodynamics, precision is everything. Whether we’re optimizing the lift of an aircraft wing, minimizing drag on a car, or — in our case — developing cutting-edge eSAIL® technology to propel maritime vessels, aerodynamic accuracy drives performance. And one of the most powerful tools engineers have to ensure this accuracy is wind tunnel testing.

With the role digital simulations now play in engineering, some readers may be thinking wind tunnels sound a bit ‘old school’. However, physical testing in controlled airflow conditions continues to provide insights that no innovative model alone can fully replicate.

This article explains what wind tunnel testing is, why it still matters in a CFD-driven world, and how it underpins reliable performance prediction for wind propulsion at scale.

What is wind tunnel testing?

A wind tunnel is a controlled testing environment in which air is artificially driven past a stationary object to recreate real-world aerodynamic conditions. Rather than moving the object through air, the air itself is set in motion — allowing engineers to precisely measure how airflow interacts with the structure being tested. Think of it as a treadmill for air—only with a lot of sensors.

In wind tunnel testing, the object (such as an eSAIL®, wing or vehicle model) is mounted inside a test section and instrumented with sensors that measure:

- Aerodynamic forces such as lift, drag and bending moments

- Pressure distribution across surfaces

- Flow behaviour, including turbulence, separation and wake effects

Different wind tunnels are designed for different purposes. Some focus on high-speed flows, others on turbulence intensity, wind shear or multi-object interaction. What they all offer is repeatability, control and physical accuracy — essential when validating complex aerodynamic systems.

Why wind tunnel testing still matters in the age of CFD

In the past, wind tunnels were the go-to tool for virtually all aerodynamic development – from aircraft design to automotive testing. With the introduction of powerful computers and sophisticated modelling techniques, Computational Fluid Dynamics (CFD) revolutionized the field, allowing engineers to simulate complex flows quickly and at a fraction of the cost. As a result, wind tunnel use declined — but it never disappeared.

CFD simulations are incredibly advanced and essential to modern aerodynamics, but they’re built on assumptions, idealizations, and mathematical models. Wind tunnel testing offers a physical reality check. It helps answer fundamental questions like:

- Are our models capturing the right flow behaviour?

- Are there unexpected flow separations or interference patterns?

- How do real-world tolerances impact performance?

So, rather than competing with CFD, wind tunnel testing complements it — bridging the gap between theory and application, providing high-fidelity data that validates, corrects, or enhances digital simulations.

How bound4blue uses wind tunnel testing to validate eSAIL® performance

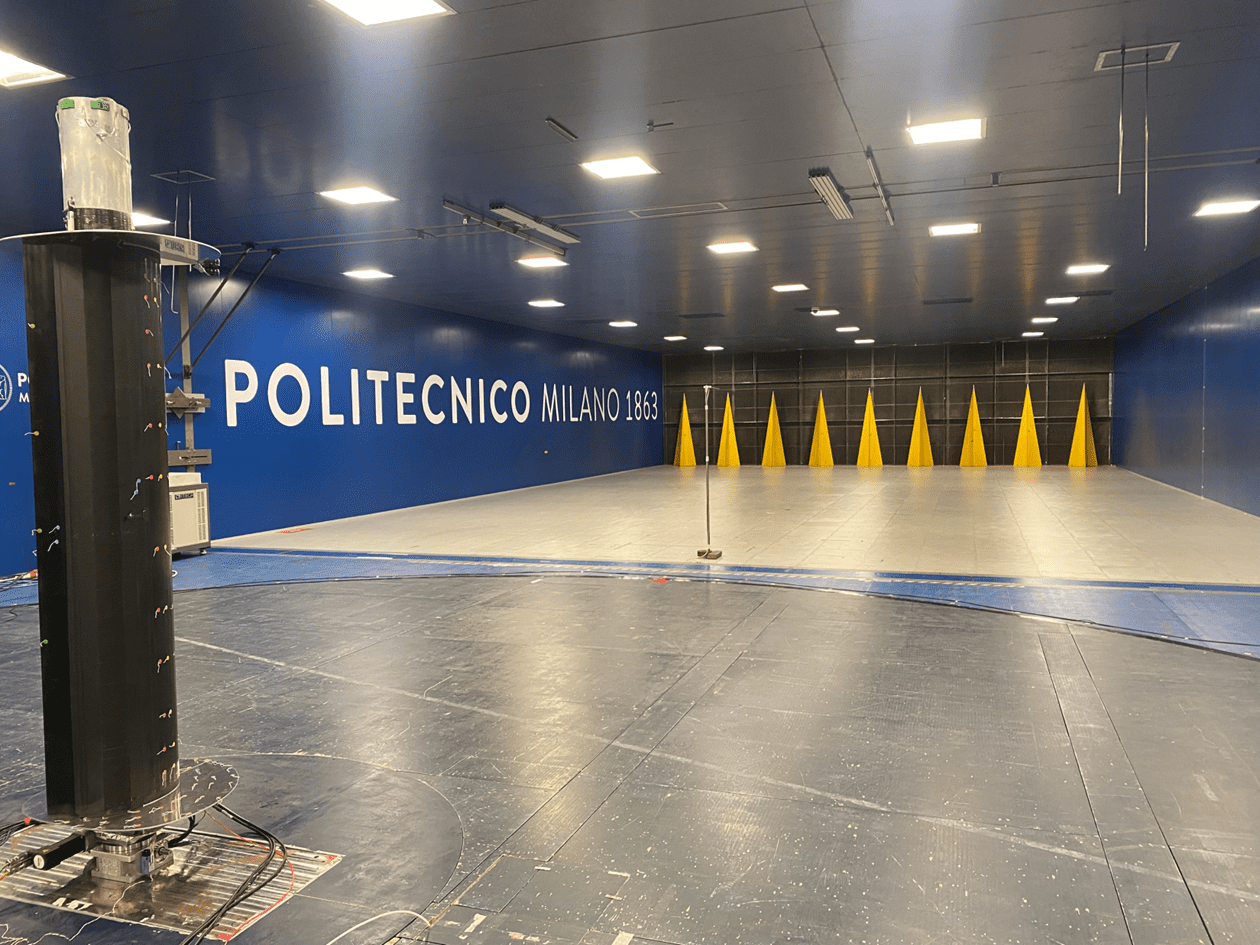

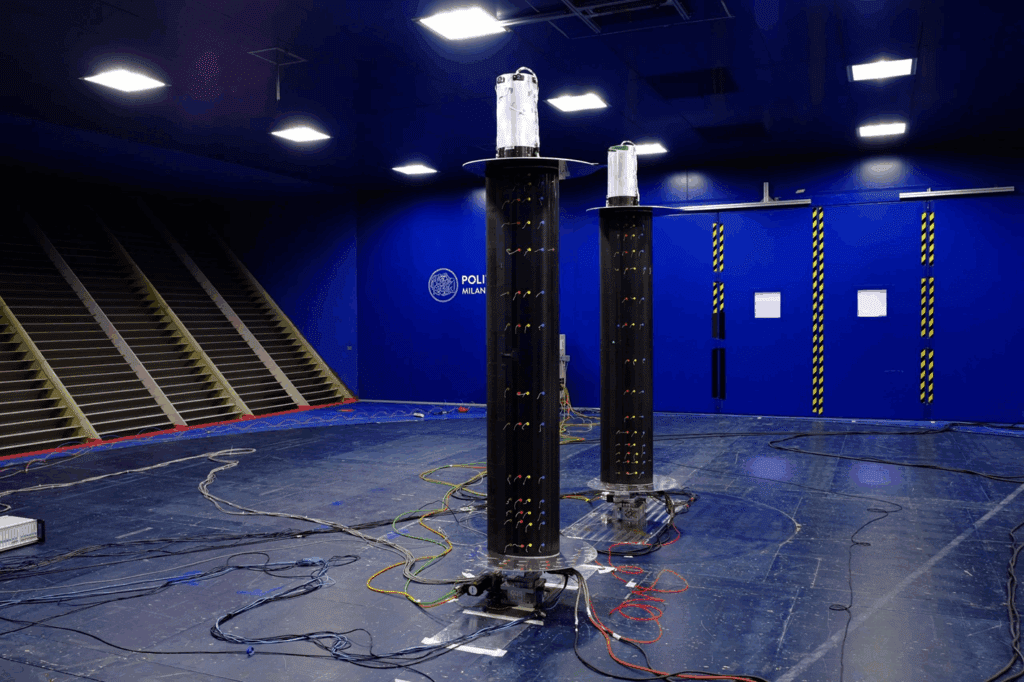

At bound4blue, our aerodynamics team recently completed an extensive wind tunnel test campaign with one mission in mind: to validate and enhance the aerodynamic performance of the eSAIL®. These tests were carried out at the POLIMI (Politecnico di Milano) wind tunnel facilities, which we selected due to their advanced capabilities — including the ability to apply variable wind profiles and accommodate two eSAIL® units simultaneously, a critical capability when studying aerodynamic interference.

The campaign focused on three key areas:

- Single-sail characterisation: Initial tests examined individual eSAIL® configurations in isolation. This allowed the team to fine-tune aerodynamic models, extend existing datasets and verify repeatability under varying turbulence levels.

- Multi-sail interaction and interference: The most complex — and revealing — phase involved testing two eSAIL® units operating in close proximity. These tests examined how airflow from one sail affects the performance of another, an effect that directly influences real-world fuel savings on multi-sail installations. Spoiler alert: it matters. A lot.

- Validation of Prediction Tools: All data collected feeds directly back into bound4blue’s aerodynamic toolkit. Wind tunnel testing enables the validation and refinement of in-house models (such as the fast interference estimation tool POINT) used to predict factors such as thrust, fuel savings and emissions reduction for specific vessel configurations. This ensures our simulations are not only efficient but trustworthy.

When our clients make decisions based on our performance predictions—whether it’s for ship routing, fuel savings, or emissions reduction — they’re relying on data backed by science and tested in wind. That’s what gives us, and them, confidence.

Why this matters for the maritime industry

Aerodynamic performance isn’t just a matter of academic interest. In commercial shipping, it directly affects:

- Fuel consumption

- Emissions compliance

- Return on investment for new technologies

As regulations such as EEXI, CII and the IMO’s decarbonisation framework tighten, shipowners increasingly rely on verified performance data when selecting efficiency solutions.

Wind tunnel testing helps ensure that wind propulsion delivers measurable, auditable results — supporting both regulatory reporting and commercial decision-making.

By combining validated CFD models with experimental data, bound4blue supports the responsible, scalable adoption of wind-assisted propulsion across the global fleet.

Wind tunnel testing as a foundation for trust

As wind propulsion moves from a niche clean-tech solution to widespread industry adoption (with 30% of the world fleet expected to embrace wind power by 2050) transparency and validation are more important than ever.

Wind tunnel testing provides:

- Independent physical evidence of performance

- Confidence in multi-sail configurations

- A robust foundation for regulatory acceptance

We’ll be sharing more insights on the results of our testing following the RINA Wind Propulsion Conference in February, where experimental results on multi-eSAIL® interference and model validation will be presented.

The big takeaway

Wind tunnel testing remains an irreplaceable pillar in the aerodynamic development process. It helps answer tough questions, validate critical assumptions, and refine technologies that shape the future of sustainable transportation.

At bound4blue, we’re proud to keep engineering with curiosity, validating with rigor, and delivering performance you can trust — with the wind to prove it.

FAQ: Wind tunnel testing and wind-assisted propulsion

Q: What is wind tunnel testing?

A: Wind tunnel testing involves measuring how air flows around a stationary object in a controlled environment to assess aerodynamic forces and behaviour.

Q: Why is wind tunnel testing still needed alongside CFD?

A: CFD relies on mathematical models and assumptions. Wind tunnel testing provides real-world validation, helping verify and refine simulation results.

Q: How does wind tunnel testing support WAPS development?

A: It allows engineers to study complex airflow interactions, including turbulence and sail-to-sail interference, under realistic conditions.

Q: Why is multi-sail testing important?

A: Most commercial installations use more than one sail. Understanding aerodynamic interference is critical for accurate performance prediction.

Q: How does this benefit shipowners?

A: Validated data improves confidence in fuel savings, emissions reduction and regulatory compliance — reducing both technical and commercial risk.