Press release

Is it a space rocket or a Transformer?

Published

30 June 2022

I thought it would be interesting to share my answer with you too, just like they would explain it on a “How it works” episode.

Ready? Let’s go!

The eSAIL is neither a rotor nor a wingsail. It is a type of wind-assisted propulsion system (WAPS) based on active boundary layer control using suction. Said in a simple way: it is a suction sail.

As you can imagine, the question that always follows is: How does a suction sail work?

Before answering this question, I have to explain first the basic principles of wind-assisted propulsion systems.

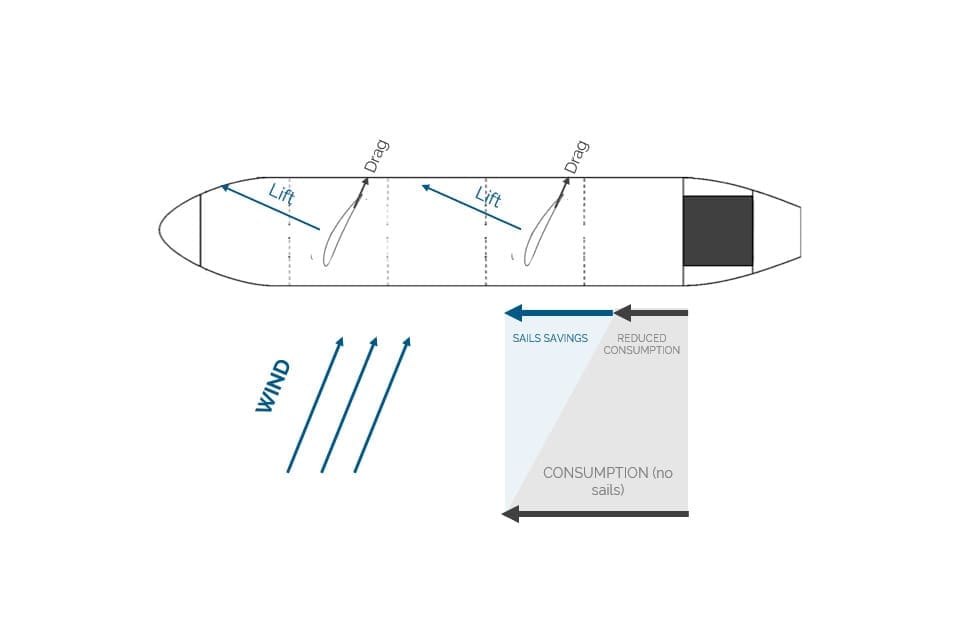

Basic principles of WAPS

Any wind-assisted propulsion system, when exposed to wind, produces two aerodynamic forces: lift (L) and drag (D). These aerodynamic forces contribute to propelling the vessel forward, so the main engine can be throttled down, all maintaining the same vessel speed. Consequently, the main engine delivers less power, reducing its fuel consumption and pollutant emissions.

At this point you might be asking yourself: If wingsails, Flettner rotors and suction sails work under the same principle as all wind-assisted propulsion devices… Why are they named differently?

That’s because the way in which these systems generate the aerodynamic forces is different.

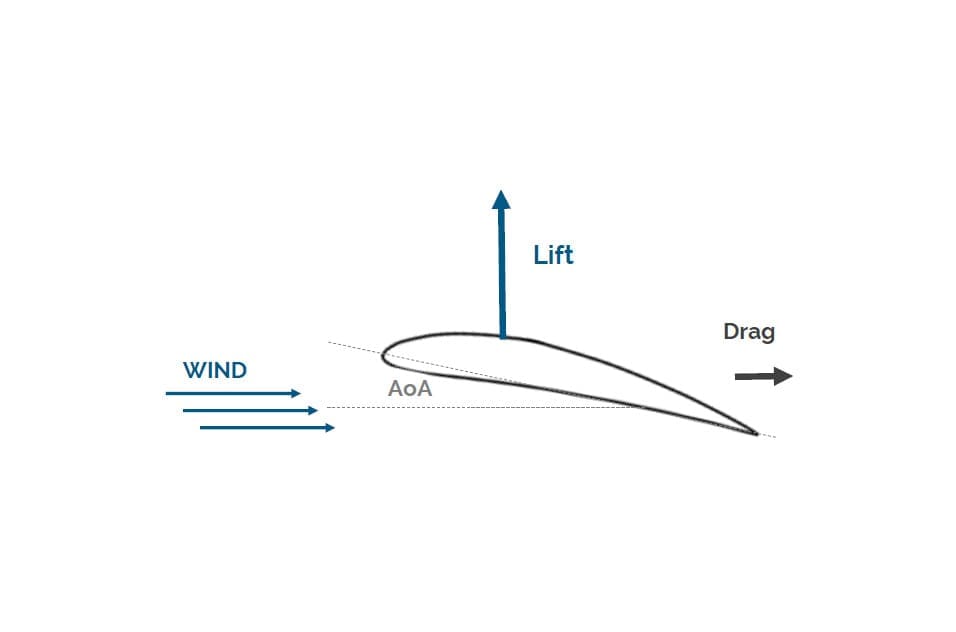

Wingsails

Rigid wingsails are “like” simplified airplane wings, and their operation is equivalent.

They have an aerodynamic shape (airfoil) that, when exposed to an airflow, produces lift (by the difference in pressure on both sides of the airfoil). The amount of lift is controlled by the inclination of the airfoil with respect to the wind (Angle of Attack – AoA) and is way below 2.

The operation is based on ensuring that the airfoil is correctly oriented to the wind (appropriate AoA), with no additional requirement of power.

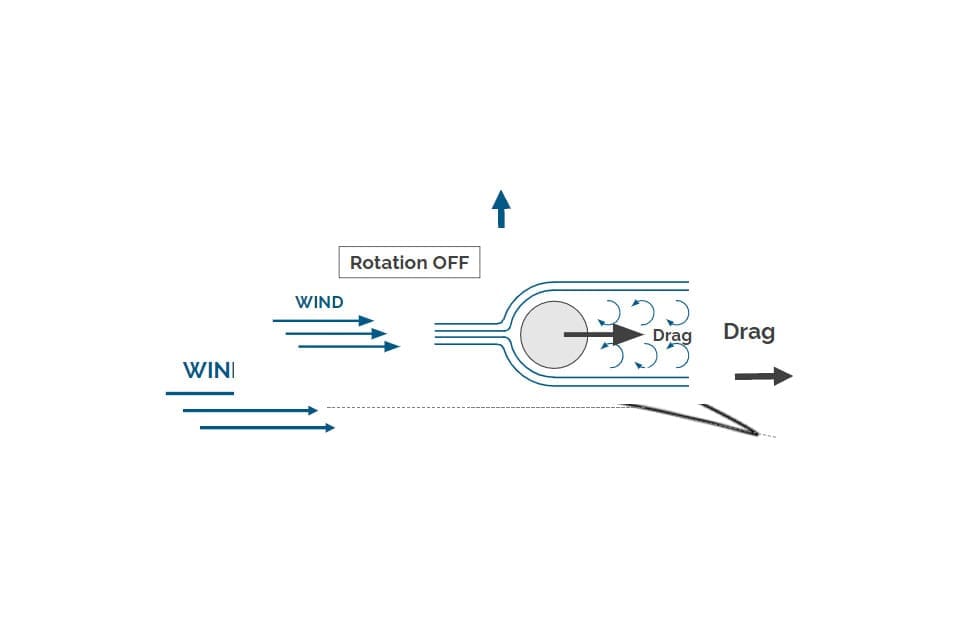

Flettner rotors

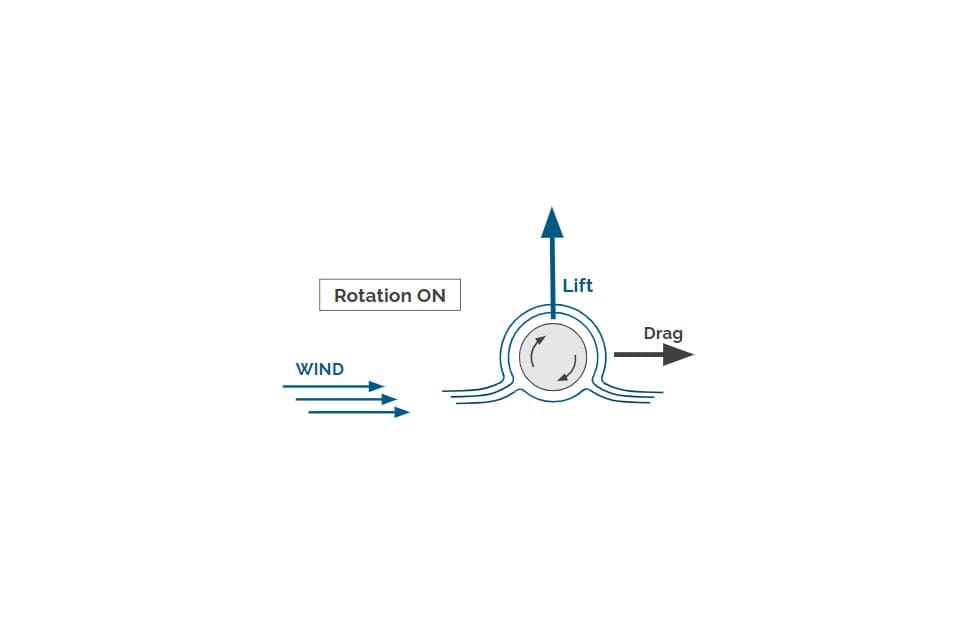

Flettner rotors are based on the aerodynamic principle known as Magnus Effect, by which a rotating cylinder in an airflow generates lift.

The airflow around a static cylinder flows symmetrically around it until it detaches from the surface, generating a turbulent area behind it, creating a very large drag force (a cylinder drag is x40 times larger than an airfoil of the same thickness).

If that same cylinder rotates, it “drags” the airflow faster on one side and slower on the other, which generates a difference in pressure (due to the difference in airspeed), resulting in a perpendicular force (Lift) and a parallel force (Drag).

The operation is based on adjusting the rotation speed of the cylinder to the wind conditions. This rotation is maintained, with the consequent high power consumption.

Suction sails

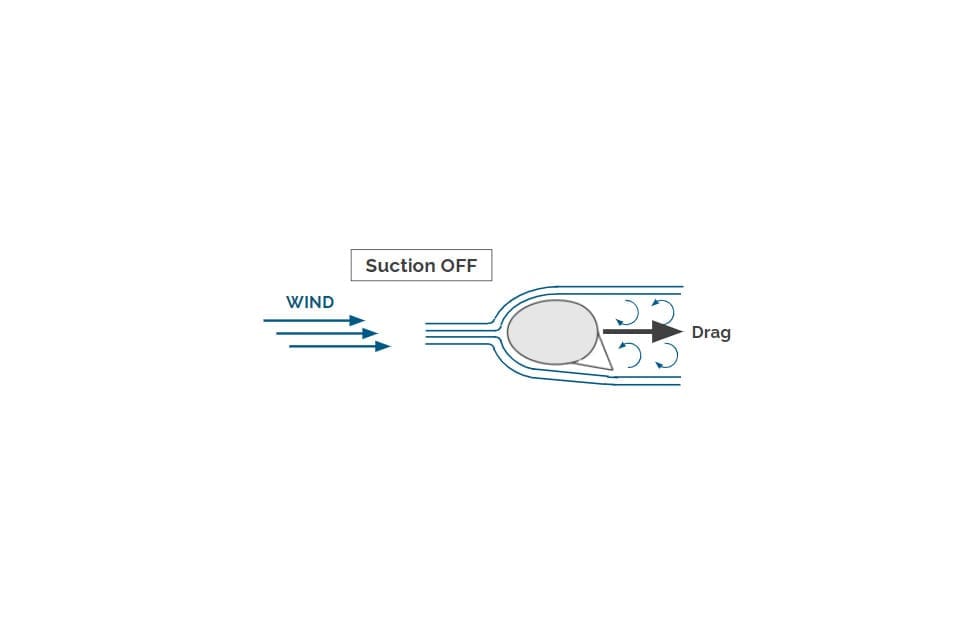

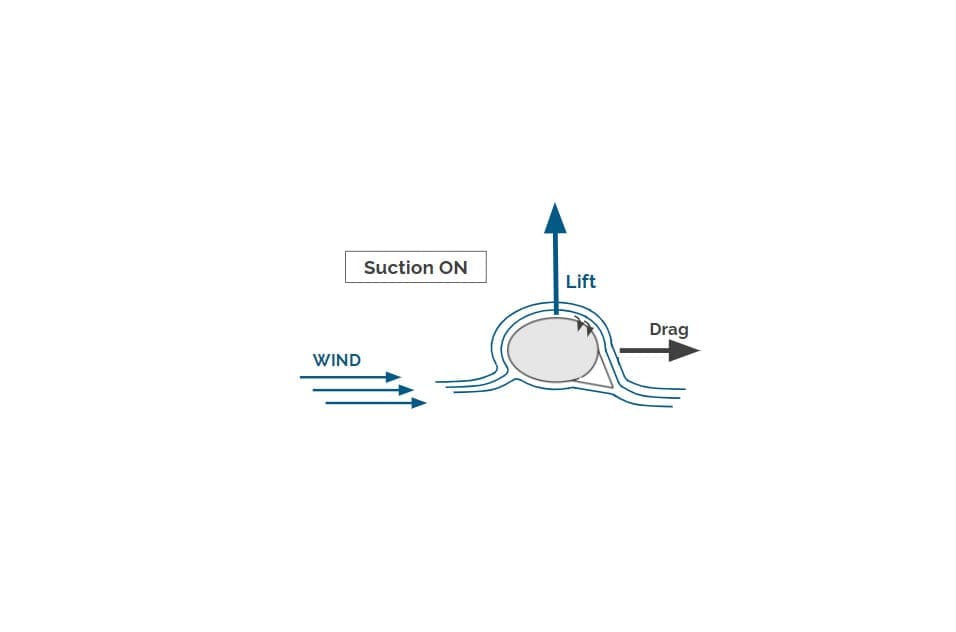

This system is composed of an egg-shaped thick profile and a flap.

The airflow around a thick airfoil would detach (similar to what happens on a cylinder), generating a turbulent area behind it, creating a large drag force.

The movable flap serves two purposes: 1) It generates asymmetry, thus increasing lift, and 2) it covers the suction area that is not in use.

The operation is the same as a wingsail, adjusting AoA (Angle of Attack) to the wind direction, and setting the appropriate aspiration to the wind conditions. Aspiration requires very low power consumption (much lower than rotor sails!).

The last question that always follows is: which one is better? I’ll leave this one for another day but, let me give you one little tiny hint:

If you still have doubts, feel free to share them with me in the comments below. I could spend hours and hours talking about wind propulsion!