News

Shipping’s second wind: how suction sails work to empower sustainable, profitable shipping

Published

16 October 2024

-

Wind power is back on the industry agenda as a renewable, available, and cost-effective way to reduce climate impact, meet regulatory demands, and drive profitability.

-

But did you know there’s a proven way to ‘upgrade’ this force of nature, supercharging its potential to push vessels to new green performance horizons?

-

Alberto Llopis PhD, Head of Aerodynamics at bound4blue, reveals the secrets of suction sails.

The majority of people probably look to the past, rather than the future, when wind propulsion is mentioned. And that creates a barrier of understanding, or rather misunderstanding.

It can be difficult to reconcile the images of sailing ships we’ve all grown up with, with the propulsive force needed to power today’s modern fleets of bulk carriers, tankers, cruise ships and other advanced cargo and passenger vessels.

As such, there can be a sense of disbelief when wind generates headlines as one of the key enablers for a green maritime future, with, for example, bodies such as the EU forecasting up to 10,700 wind propulsion installations by 2030.

How could this be possible? Why is wind such a ‘hot topic’? Well, one simple reason is the scale of benefits.

➡️ Download all case studies to see the benefits of the suction sails ⬅️

Rewarding choice

Wind is a renewable energy source that is free, abundant and readily accessible, with absolutely zero supply chain and infrastructure development demands.

When harnessed efficiently – which we’ll get on to shortly – the propulsive power provided dramatically reduces main engine loads and fuel consumption. That means lower OPEX, lower emissions and, a key point in the regulatory climate of today (and tomorrow), easier compliance, with huge rewards in terms of factors such as CII, EU Emissions Trading Scheme (EU ETS) and the upcoming FuelEU Maritime legislation.

So, the ‘how and why’ in that respect are so straightforward it’s almost a ‘no brainer’. The benefits really do speak for themselves. The ‘how’ in terms of the technology, however, demands a little more cognitive flexing. But not, I hope, as much as you might think.

Leading the charge

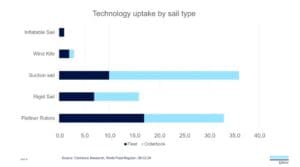

There are several types of wind assisted propulsion (WAP) technology available. These include rigid sails, kite sails and Flettner rotors. However, according to findings from Clarkson Research/World Fleet Register, it’s suction sails that are positioned to take pole position on the industry orderbook, with broad-based suitability for a huge range of vessel segments.

So, what is a suction sail?

The first suction sail was developed in the 1980s by the Cousteau Foundation, with a team led by Professors Lucien Malavard and Bertrand Charrier PhD, who were unconvinced by both rigid sails and Flettners. Although a system was successfully tailored for the Calypso II research vessel, the race towards commercialisation paused, before bound4blue took the development baton and ran with it.

Today bound4blue offers the eSAIL®, a fully autonomous system, with low weight, high flexibility, few moving parts and low maintenance requirements, that uses advanced aerodynamics to generate exceptional propulsive efficiency. It’s almost as easy to understand as its benefits… once we go ‘back to basics’ a little.

Generating interest

To get to grips with suction sails we need to pay a visit to rigid sails and say hello to three fundamental aerodynamic concepts.

Namely: lift and drag; angle of attack; and stall.

‘Lift and drag’ refers to the two aerodynamic forces that any shape experiences when air flows around it. In aircraft, lift is the force that pushes you upwards and drag is a resistance which pushes you backwards. Lift is always perpendicular to the wind direction and drag is parallel. In wind propulsion, these same forces are utilised to propel vessels forward.

In aerodynamics, instead of using lift and drag forces to quantify performance, we actually use “Coefficient of Lift” and “Coefficient of Drag” (CL and CD). These are values that allow us to quantify how much force a body generates independently of size and wind conditions. But more importantly, it allows us to compare the performance of different shapes.

The ‘angle of attack’ refers to the angle between the wing/sail and the wind. So, let’s see how these interact.

In the video you can see a symmetrical aerofoil with an angle of attack of zero. The air flows around the foil with zero lift. However, if we increase the angle, we increase the generation of lift force. In other words, we have power.

Great, maximise the angle, maximise the propulsion, you may be thinking. But, it’s a careful balancing act.

If the angle surpasses a certain point (the critical angle) the flow of air separates from the aerofoil resulting in a sudden drop in lift (with plenty of drag). This is where the ‘stall’, or loss of power comes in. Problematic for a ship, disastrous in aviation.

Now we know this, let’s supercharge things with the ‘suction’ concept.

Fanning the winds of change

If you happened to be sat next to an aerodynamic engineer at a dinner party they’d happily inform you that the above principles working with a symmetric rigid wing would deliver a maximum Coefficient of Lift of 1.2.

After asking yourself why you were having this conversation, you may then quiz the engineer on how to push this all-important CL to new heights. This was exactly what the team at the Cousteau Foundation asked themselves.

The maths tells us that the first port of call in the quest for more lift is creating a thicker profile for the aerodynamic surface. But the maths don’t help us if the air flow is detached and we’ve stalled.

So, how can we stop detachment? The answer is suction. By adding suction along key points of the body, the flow remains attached and we see a significant increase in lift coefficient.

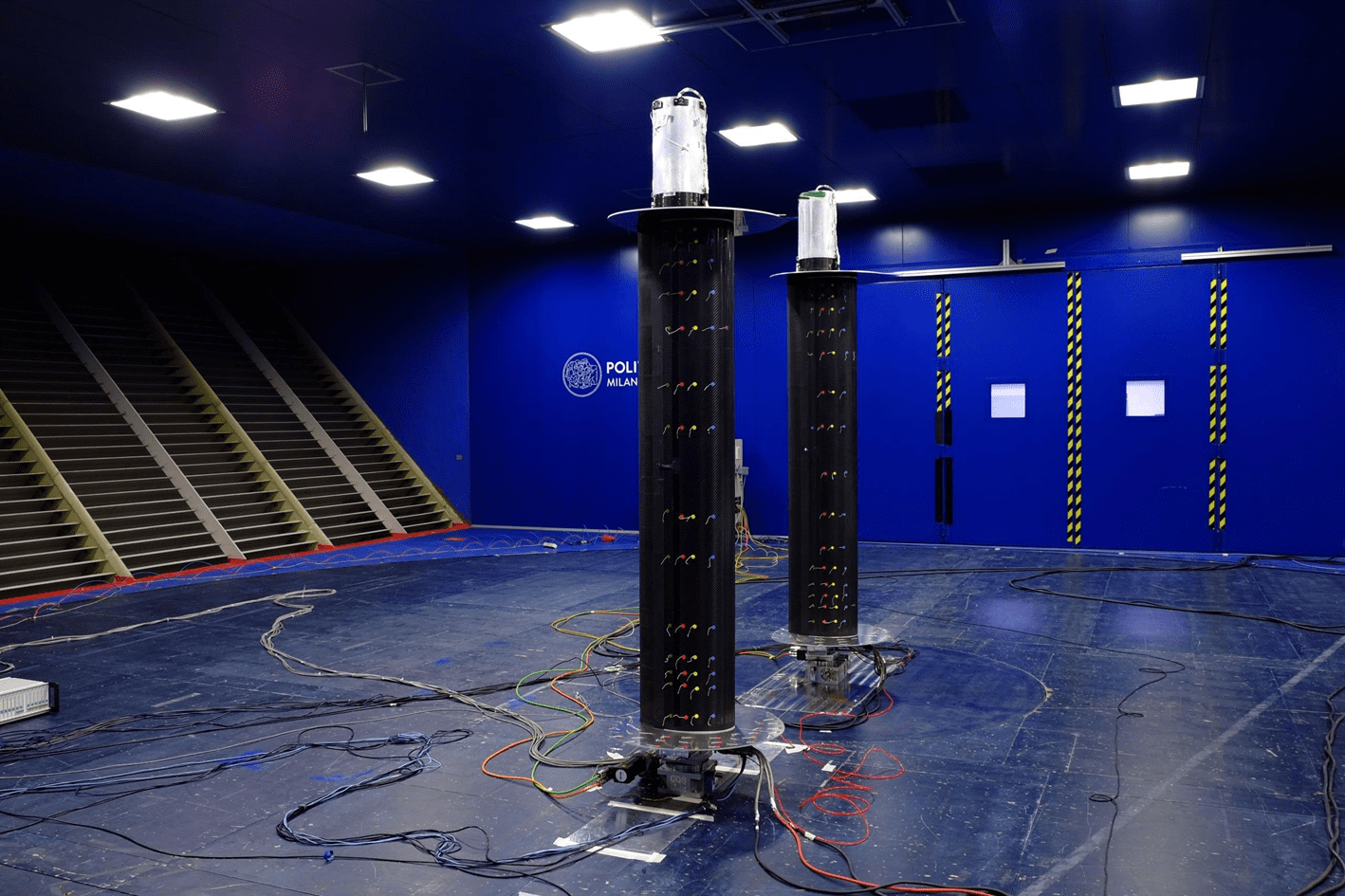

In bound4blue’s case this is achieved by introducing a fan at the top of the eSAIL®, while the body of the sail itself features a porous grid. This allows air to flow inside the sail, the air rises towards the fan and is then expelled. Not only does this create greater lift on a sail with a zero angle of attack (a CL of 2.4 – twice the maximum of a standard rigid wing!), but the fact that the air ‘sticks’ to the surface means the angle of attack can be boosted far beyond the normal stall inducing point, from around 12 to 60 degrees.

Shipping’s superpower

bound4blue’s eSAIL® has a maximum CL of 8.3. This is six to seven times greater than a conventional rigid wing sail. That means six to seven times the power generation, or, to put it another way, the same thrust from a unit that is 6 to 7 times smaller than a conventional system.

And yes, this breakthrough system is good at sailing upwind as well as downwind.

Now, maybe you can begin to understand the potential of this technology for modern ships, and global green supply chains as a whole. Beyond propelling vessels, this has the power to accelerate maritime’s energy transition… today!

Enabling the future

This is the just the ‘101’ on suction sails, but I hope it gives you a better understanding of the ‘how and why’. There’s far more to discover, with strong reasons why forward-thinking owners and operators such as Eastern Pacific Shipping, Louis Dreyfus Company, Marflet and Odfjell, to name a few, have placed recent eSAIL® orders and joined the wind revolution.

The combination of the commercial, regulatory and environmental impact is what may drive the decision making – aided by a typical return on investment of less than five years – but it’s the simple, robust and innovative aerodynamic technology that truly enables these headline benefits. Technology that you now understand.

Perhaps you also appreciate why we hope stakeholders think of the future, rather than the past, next time wind propulsion is discussed. We believe it can power this industry towards its most ambitious green goals. And that’s enough to give us all a Lift!

About the author

Alberto Llopis Pascual holds the current position of Head of Aerodynamics at bound4blue. He is responsible for aerodynamic development of bound4blue’s technology, both numerical and experimental. Alberto holds a PhD in Aerospace Engineering in the field of experimental aerodynamics (University of Manchester, 2017). Previously, he spent 6 years working with University of Manchester, BAE Systems and a NATO task group researching and developing fluidic control effectors for aircraft, designing, and building the first aircraft to fully integrate and demonstrate this technology. Later, he also spent 2 years carrying out aerodynamic design of medical delivery drones.